Ceramic 3D printed sweeping surfaces

Computers & Graphics

aSchool of Computer Science and Technology, Shandong University bSchool of Mechanical Engineering, Shandong University

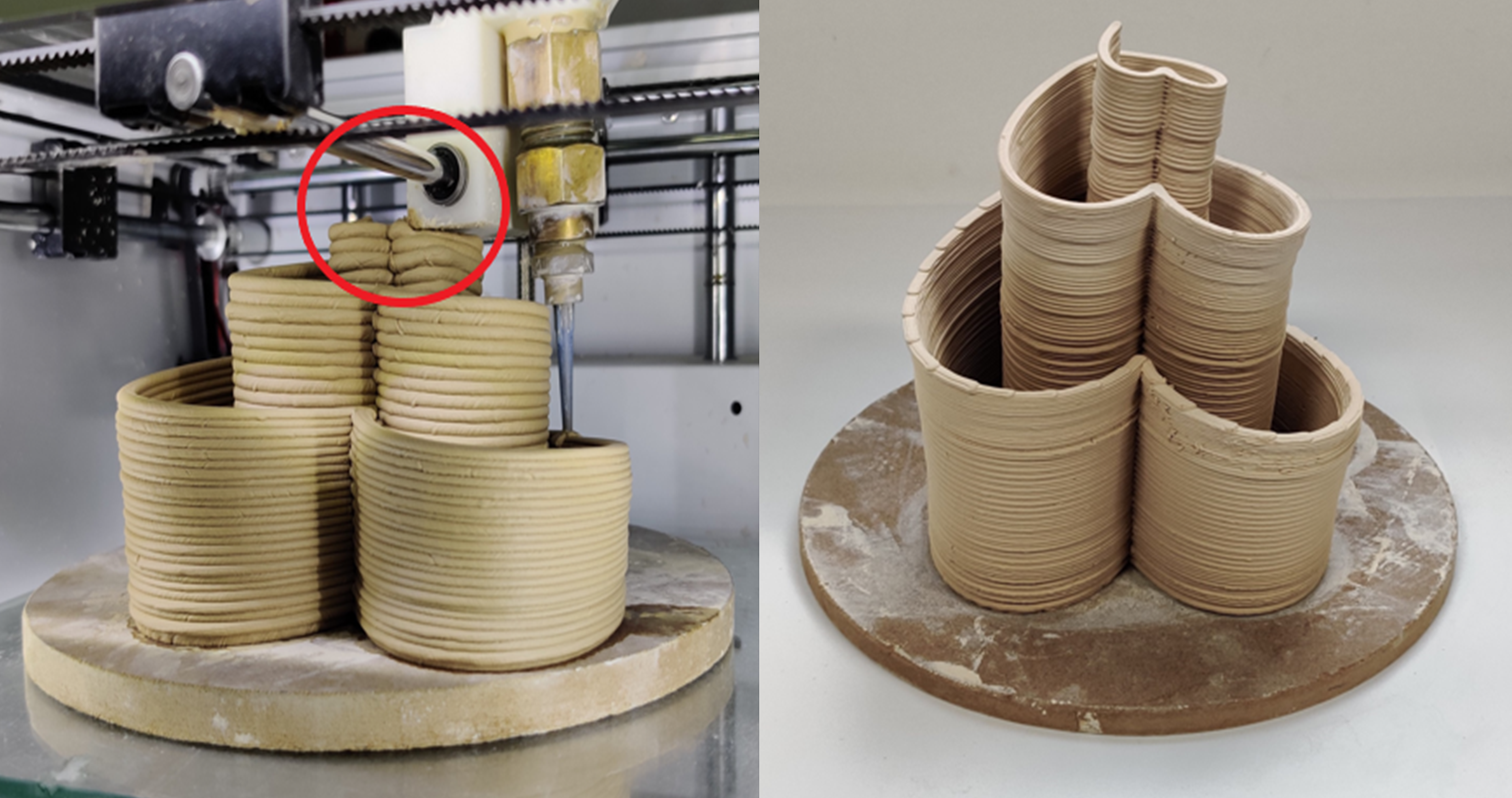

Some models designed by common users using our modelling tool and fabricated on desktop ceramic 3D printers CERAMBOT.

Abstract

Ceramic 3D printing has gained rapid development in recent years. Especially, desktop

ceramic 3D printers get more and more popular for designers, artists, and makers

to work with clays. As a highly viscous pseudoplastic liquid, the printing material

clay produces featured aesthetics, and also indicates several manufacturing constraints.

There are barely customized modeling tools for ceramic printing. Targeting for ceramic

printing, we present a user-interactive modeling and fabricating framework using

sweeping lines as the design tool. We integrate the ceramic printing constraints like

self-supporting and collision-free in the modeling stage. Then we propose a customized

method for generating the printing file, with the guarantee that the extruder traces a single

continuous path without starts and stops. To fulfill this goal, we compute an adaptive

zig-zag path along the sweeping surface. During the fabrication, our continuous

path avoids the potential collision between the printing head and the physical model.

Moreover, we optimize the extrusion amount along with the extruder movement, such

that overlap between neighboring layers is appropriate in terms of both model stability

and cost-effectiveness. We demonstrate the fabrication process and physical results to

validate our method.

Video

More Results

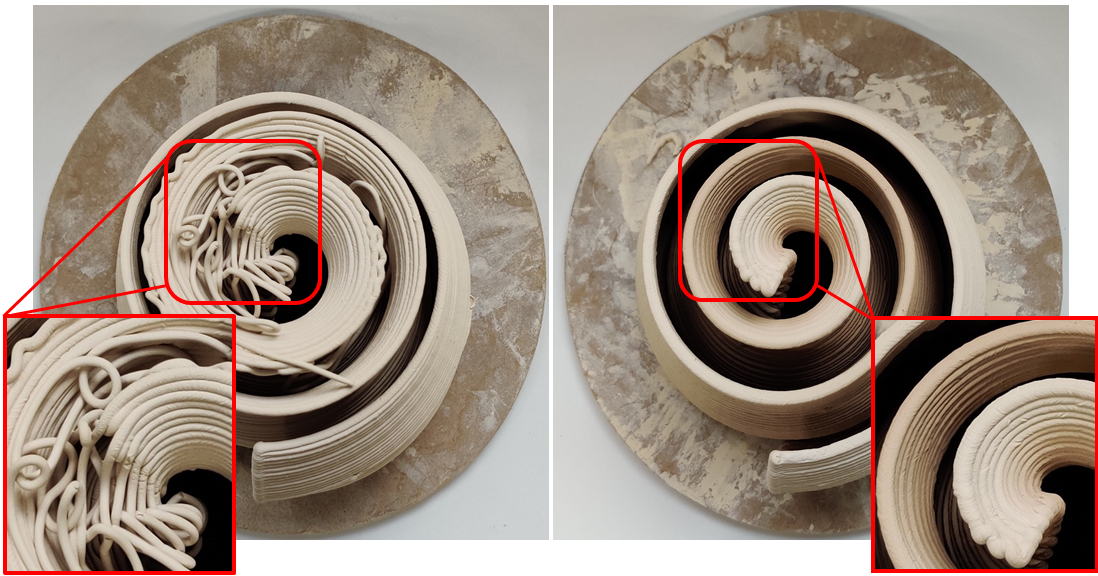

Adaptive zig-zag path algorithm: deal with the possible collision between extrusion head and printed model(left picture).

Adaptive extrusion amount computation: optimize the extrusion amount so that it's appropriate in terms of both model stability and cost-effectiveness(right picture).

Some materials with similar properties to clay can also be used for 3D printing through our framework, the picture shows the chair we fabricated with cement.

Downloads

Acknowledgement

We thank all the anonymous reviewers for their valuable suggestions. This work is supported by grants from NSFC (61972232), State Key Laboratory of Virtual Reality Technology and Systems (VRLAB2019A01), Key basic research project of Natural Science Foundation in Shandong province (ZR2018ZB0106) and the Key Science and Technology Innovation Project of Shandong Province (2019JZZY010112).

BibTex

@article{ZHONG2020,

title = "Ceramic 3D printed sweeping surfaces",

journal = "Computers & Graphics",

year = "2020",

issn = "0097-8493",

doi = "https://doi.org/10.1016/j.cag.2020.05.007",

url = "http://www.sciencedirect.com/science/article/pii/S0097849320300583",

author = "Fanchao Zhong and Wenqiang Liu and Yu Zhou and Xin Yan and Yi Wan and Lin Lu",

keywords = "Sweeping surface, Ceramic 3D printing",

}