Strong 3D Printing by TPMS Injection

IEEE Transactions on Visualization and Computer Graphics

aShandong University bBen-Gurion University of the Negev cPeking University

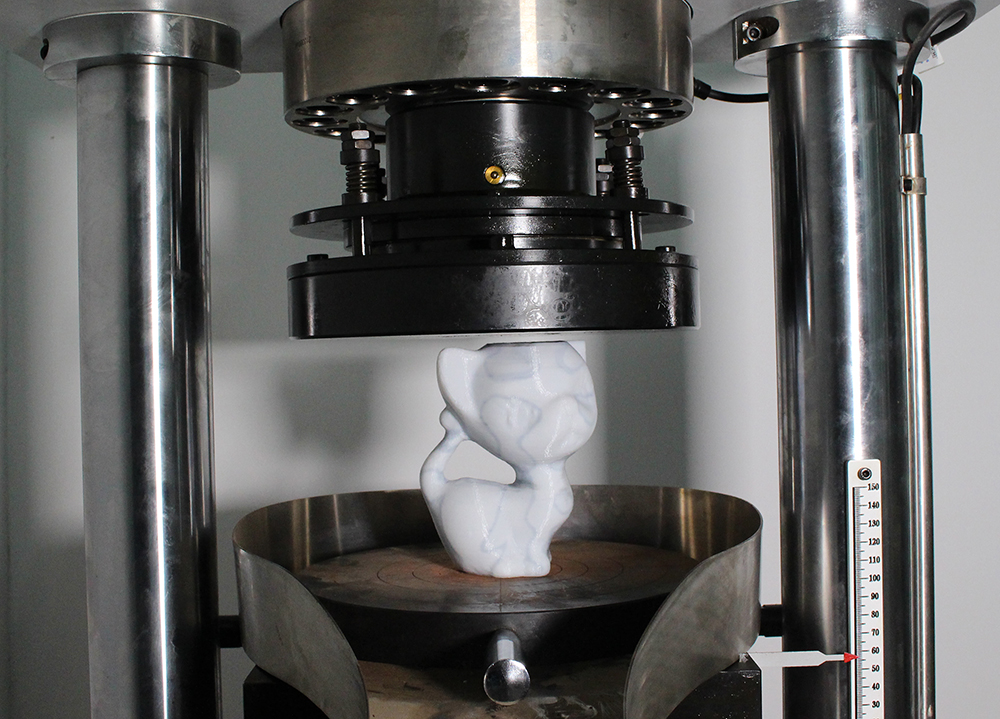

The interior TPMS channel of a 3D kitten is injected with strong blue resin. The translucent rendered 3D kitten with optimized interior TPMS channel (leftmost), the 3D printed kitten sliced for visualization purposes of the TPMS channel structure (mid) and infill distribution (rightmost).

Abstract

3D printed objects are rapidly becoming prevalent in science, technology and daily life. An important question is how to obtain strong and durable 3D models using standard printing techniques. This question is often translated to computing smartly designed interior structures that provide strong support and yield resistant 3D models. Nevertheless, computation and optimization of interior structures are challenging tasks that require careful design especially in presence of complex geometries and topologies. In this paper we suggest a combination between 3D printing and material injection to achieve strong 3D printed objects. We utilize triply periodic minimal surfaces (TPMS) to define novel interior support structures. TPMS are closed form and can be computed in a simple and straightforward manner. Since TPMS are smooth and connected, we utilize them to define channels that adequately distribute injected materials in the shape interior. To account for weak regions, TPMS channels are locally optimized according to the shape stress field. After the object is printed, we simply inject the TPMS channels with materials that solidify and yield a strong inner structure that supports the shape. Our method allows injecting a wide range of materials in an object interior in a fast and easy manner. Results demonstrate the efficiency of strong printing by combining 3D printing and injection together.

Video

More Results

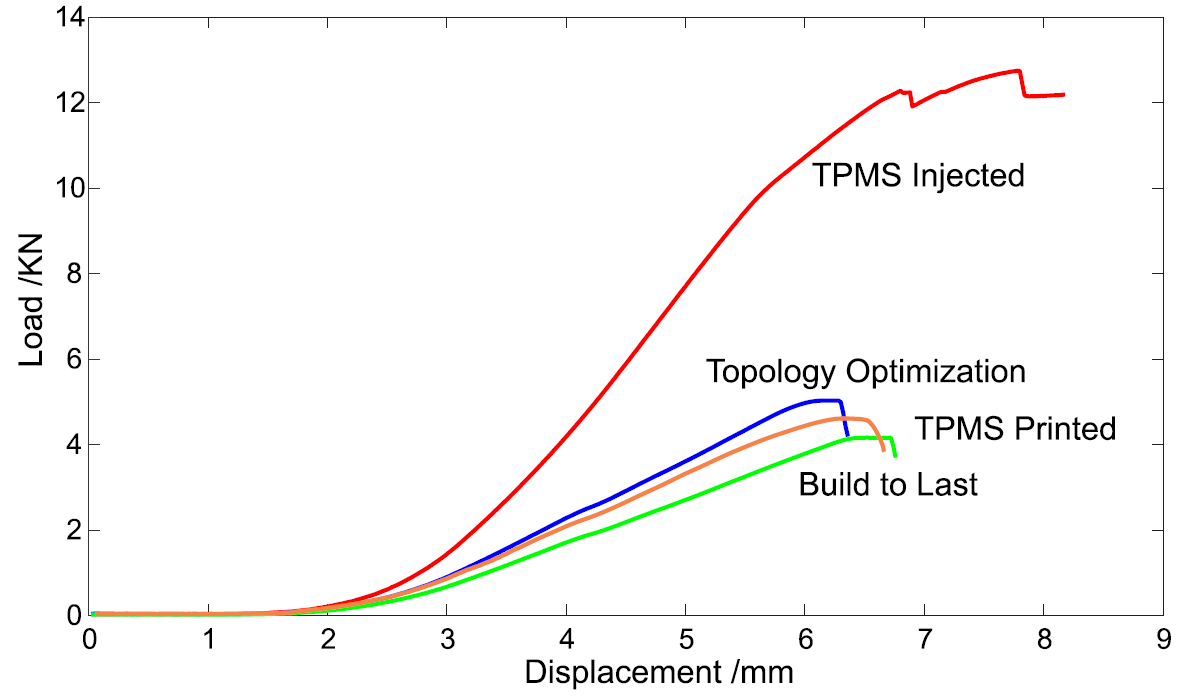

Load-displacement curves: TPMS channel injected with epoxy resin (red), TPMS channel printed in PLA (orange), topology optimization[23] (blue) and honeycomb-cell [1] (green).

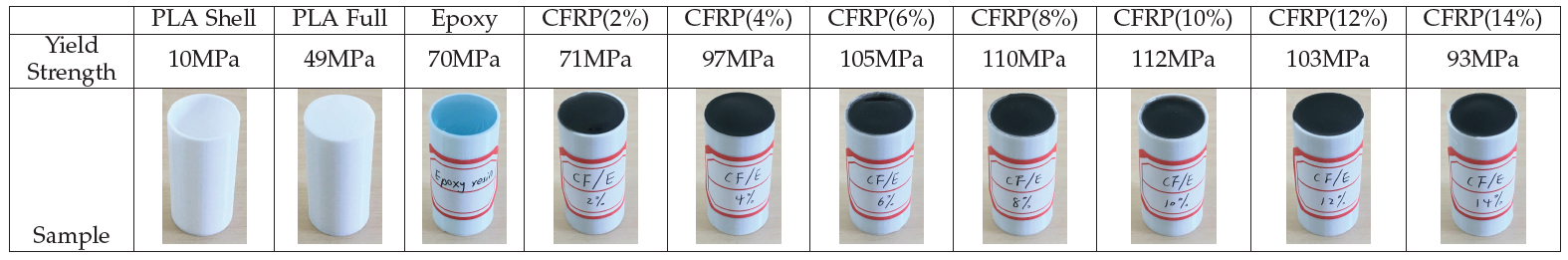

Experiments on the injected materials. We tested the strength for different compositions of the carbon fiber reinforced polymer (CFRP) and compare with the 3D printed material PLA.

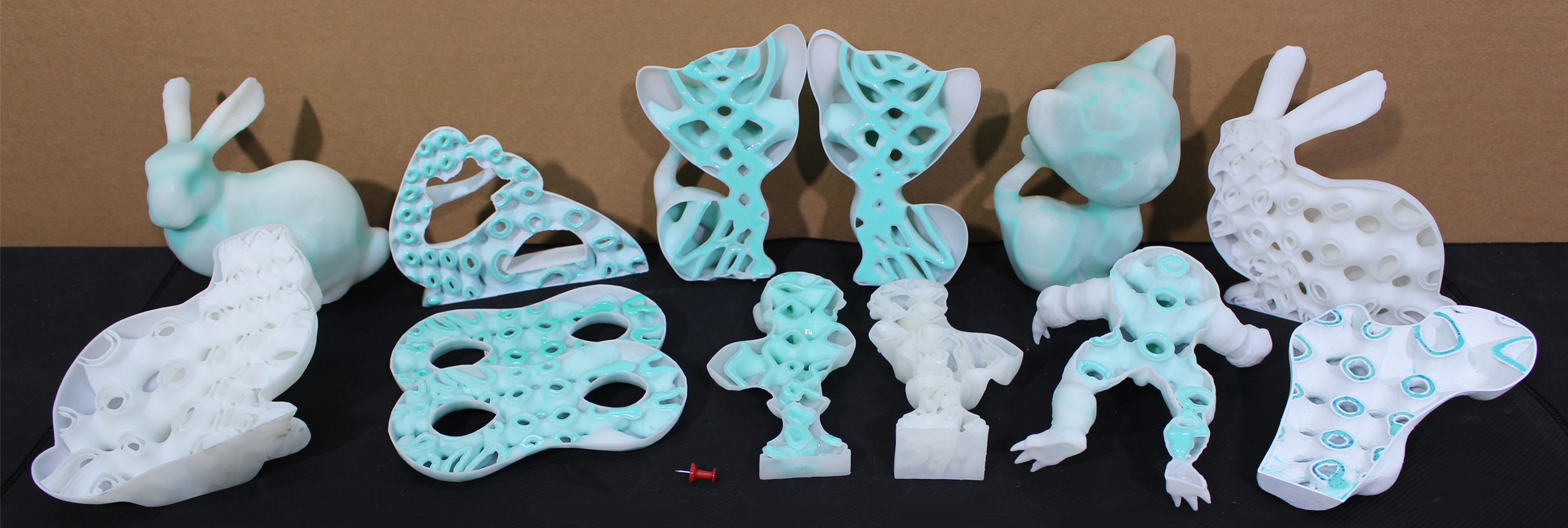

3D printed models with TPMS channels inside. Some models are injected with blue epoxy resin. Some are left no injection for illustrating the channels.

Downloads

Acknowledgement

We thank all the anonymous reviewers for their valuable comments and constructive suggestions. We thank Prof. Daniel Cohen-Or for his ideas and discussions. This work is supported by grants from National 973 Program (2015CB352501), NSFC (61572291), and Young Scholars Program of Shandong University (YSPSDU). Sharf’s work was partially supported by his ISF and GIF grants.

BibTex

@ARTICLE{Yan2020,

author={X. {Yan} and C. {Rao} and L. {Lu} and A. {Sharf} and H. {Zhao} and B. {Chen}},

journal={IEEE Transactions on Visualization and Computer Graphics},

title={Strong 3D Printing by TPMS Injection},

year={2020},

volume={26},

number={10},

pages={3037-3050},

doi={10.1109/TVCG.2019.2914044}

}